Digital Hoist Supervisor RJ99

GENERAL CHARACTERISTICS

Speed/Position Monitor RJ-99 is a set of devices responsible for a safe and effective work of the mining shaft hoist. It fulfils all rules of the Polish Mining Law and accomplishes following functions:

- Creation of the speed pattern in form of speed diagram in the function of position (conveyance's speed/position model),

- Creation of speed envelope (flanger) and overspeed control envelope (flanger) in the function of position,

- Position indication of the conveyance within the shaft in form of:

- Rough indicator (moving point indicator)

- Exact indicator - digital LED display

- Depth switches - relays switched on/off in function of position

- Speed control

INTERNAL STRUCTURE

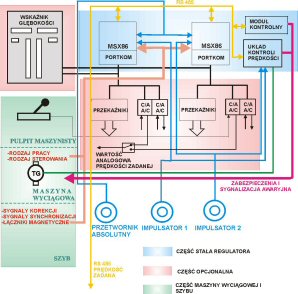

Digital Hoist Supervisor RJ-99 consists of following units:

- doubled MSX86 regulators each for every conveyance,

- speed control unit KP - MARK

- control module MK

- the set of position projecting elements: absolute encoder and two incremental encoders

- set of peripheral devices employed depending on the needs:

- position indicator

- depth relays in modules of 8 or 16 relays

- D/A and A/D converters for outputting the pattern speed value

SPEED PATTERN DIAGRAM

Speed pattern diagrams - speed curves - are tables created within the MSX86 memory, where the pattern speed for each 10cm of the conveyance's route is dynamically generated by the MSX86 software at the beginning stage of each hoist's cycle. Each of the MSX86s independently elaborates the pattern speed signal on the basis of the value read from the speed curve table according to its actual position. The speed signals deriving from both MSX86 regulators are compared in control module MK and after one of them is chosen by means of a switch and output via D/A converter in a 0-10 V signal form or directly in digital form via serial or parallel link.

SPEED CONTROL

MSX86 regulators execute continuous and points' speed control algorithm. The Speed Control Unit KP performs in an independent way continuous and point speed control and the speed pattern falling check on the slowing down way. It uses common encoders along with an tachogenerator for checking purposes for defining the conveyance position.

PARAMETERS SETTING

MSX86 regulators are provided with operator's panels with simple keyboards and LCD screens for parameters setting and diagnostic purposes. Operator panel is equipped with an EEPROM parameters memory for storing major data indispensable for the regulator's work. Essential hoisting parameters and other important data defining the regulator's operating mode can be entered by the user by means of those panels. These parameters are:

- dimensions of the shaft,

- quantity and location of magnetic switches,

- type and diameter of rope carrier (drum or friction hoist),

- accelerations, retardations, max. speed and characteristic points of speed curves for each hoist operating mode,

- maximal speed and spurt ,

- switching points of relays

POSITION INDICATOR

Display unit for conveyance position indication WG is in-built in hoist's control desk. It consists of both ''moving point'' and digital position display and the digital speed display modules. Additionally one or more relay modules can be used to discrete project the position in form of binary signals to indicate the presence of the conveyance in certain points or zones within the shaft.

SAFETY OPERATION

The safety concept of the RJ99 operation is based on dual-channel processing with a procedure protected ''safe comparator'' performed by the control unit MK. For higher safety of operation an additional module - speed control unit KP, made in different technology and equipped in different software - executes continuous and reliable monitoring of speed and braking.